What do you do when heavy snows destroy the only bridge that hikers can use to cross a fast-running and dangerous river? You get out there and build a newer, better one by hand, of course!

I’ve been doing volunteer trail work with Washington Trails Association since I moved to the Seattle area eighteen years ago. It’s fun, interesting, and lets you learn new skills while giving back to the hiking community in ways that make hiking safer and more fun for everyone. If you live in Washington State or in an area with a volunteer trail maintenance agency, I highly recommend you check them out. It’s a lot more fun than you would think, and no experience is required!

As of the summer of 2011, the only work parties I had participated in were the one day weekend work parties. These are convenient for anyone working typical office hours like I was, since you only have to show up between 8:30 and 3:30 on a weekend day of your choosing. If I selected a work party that required several hours of travel to reach, then I’d usually sign up for two consecutive weekend days and camp near the work site on Saturday night, but that’s the most I had ever worked at one time.

So about five years ago I started considering longer trips with WTA. One of the options was to join a Backcountry Response Team, or BCRT. These teams backpack into the backcountry much farther than would be practical for a single day work party and do trail building or repair combined with overnight backcountry camping. The workparty typically lasts four days, and each participant brings everything they need to survive, including tent, sleeping bag, food, and a way to purify water. I believe the tools for trailwork are usually brought in by pack animals, as it would be too difficult to carry in those heavy tools as well as all personal gear.

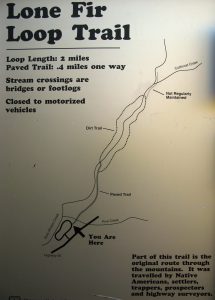

The Lone Fir Loop Trail is a short trail beginning at the Lone Fir Campground, in the Okanogan National Forest, Washington.

One BCRT in the list of upcoming trips in June that year caught my attention, because it was located in a beautiful area in the North Cascades at the Lone Fir Campground, a campground I had visited the year before when shooting fall color photography. I talked about that trip last week in Six Years Ago in the North Cascades.

This project did not require hiking into the backcountry as is typical of a BCRT, but did require a dedicated and somewhat experienced crew that BCRTs tend to attract. While most extended projects can tolerate a new crew each day as happens when a series of daily workparties tackle a project, this was to be a serious bridge building project where skills acquired one day would be a valuable asset in the following days. It was also about three and half hours from Seattle, and it would be easier to staff the project consistently this way.

Anyway, because the project site was only 0.4 miles (0.6 km) from the campground where we parked our cars, this trip would be considered a Frontcountry Backcountry Response Team effort. It would also require at least two BCRTs to complete due to the amount of work involved.

A bridge flattened by heavy snow load rests on the creek bottom as the log for the new bridge sits on the opposite shore, in the Okanogan-Wenatchee National Forest , Washington.

And what exactly was the project? Well, it seems that this trail had been built to be ADA (Americans with Disabilities Act of 1990) compliant, including a paved trail and a wide, accessible bridge across the Early Winters Creek at the 0.4 mile mark. Unfortunately for the bridge, although well built, the snow load on a flat, wide surface in the North Cascades is tremendous in the winter, and the three huge stringers under the bridge decking failed.

The accessible portion of the trail ended just past the bridge as the trail ran through a swampy area using puncheon, which is a series of logs split lengthwise and placed across the trail with the split side facing up. This sort of construction is the exact opposite of accessible. Therefore, it was decided that the accessible bridge would be replaced with a single log that would allow snow to sluff off easily and would not fail during heavy winter snows. The accessible portion of trail would simply have to end before the bridge rather than after.

So all we had to do was lift a roughly 13,000 lb (about 6,000 kg), 65 ft (20 m) log across the creek (which was more like a raging river than a creek) and drop it in place! Well, there was a good bit of finishing work to be done as well!

Dan sets the blocks needed to move the log with assistance from Marcella, in the Okanogan National Forest, Washington.

So how exactly do you do that without heavy equipment like cranes to move things around? Well, first you find a very experienced Forest Service engineer, get a bunch of tools including cables, pulleys, and griphoists, and then find a bunch of volunteers with nothing better to do for a few days!

When the week of the project arrived, some of the volunteers drove up the night before the first day of work, but I elected to wait until the first morning to drive up from Seattle. I pulled into the campground at 8:29 AM, exactly one minute before our scheduled arrival time, and found everyone sitting on a log in one of the campsites, dressed in their work clothes and waiting for me. I leaned out the window of my car and said “Am I early? You know how I hate being early!”. One the volunteers, Marta, answered back, “Yes, Ed, take one more lap around the campground!”.

So I quickly parked my car, joined the group, and off we went down the trail. We had one gasoline-powered cart to haul equipment, but what didn’t fit in the cart we had to carry. No worries, it’s less than a half-mile to the site and we had no backpacking supplies to carry.

What occurred the rest of that week in June and the week of the follow-up BCRT in September was nothing short of amazing. The tree we were to use had already been cut down and was drying, reducing its weight from an estimated 18,000 lbs (over 8,000 kg) to an estimated 13,000 lbs (about 6,000 kg) by the time we had to deal with it. It now needed to be stripped of its bark, dragged over to the creek’s edge, and hauled across the creek, all using nothing but manual labor.

After the bark was stripped, Dan, the Forest Service engineer, used a chain saw to cut grooves in the top of the log. We then used an adze to make a flat surface for walking.

Dan was tasked with rigging all of the cables, blocks, griphoists, and other components necessary to move and position the log. We actually helped with this process quite a bit, but it was Dan who had to climb high into the trees to place the pulley blocks needed to support the log.

The configuration of cables was interesting. Two cables were strung from high up in trees across the creek from the log, and were then attached to the front of the log. After running through the blocks up in the trees, the cables came back down to griphoists on the log side of the river. We would use those griphoists to move the log across the river, about a half-inch at a time.

Cables are attached and we are ready to start moving the log across the river, in the Okanogan National Forest, Washington.

The weight of the log would have simply pulled the supporting trees over into the creek, so Dan had to rig a second set of fixed horizontal cables from the tops of the support trees to the base of other trees further up the hill. Finally, one cable was attached to the rear of the log and connected via a third griphoist to a tree behind the log. This was for control, to keep the tail of the log from moving around and potentially rolling into the river, possibly killing some of us in the process. The operator of this third griphoist was to let out cable on Dan’s command, but not nearly fast enough to suit me as one of the operators of the forward-moving griphoists. You would not believe the tension these cables were under, and the effort required to work the hoists!

Ed operates the griphoist to move a 13,000 lb log into place, in the Okanogan National Forest, Washington.

After the log was suspended across the creek, we lowered it onto sills that we had also cut down, stripped of bark, and spiked into place where the trail approached the creek on each side.

This was all we could accomplish the first week, so we turned the unsupported log on the flat side and went home.

Dan scores the sides of the log where the posts will be attached as Ed holds the pattern that will be used to align the angle of the posts, in the Okanogan National Forest, Washington.

In September we resumed work, turning the log right-side up and securing it properly to the sills. We created stairs to reach the log, and put on the railing posts. To attach the railing posts, we used a big electric drill powered by a portable generator to create holes in the posts. Dan scored the side of the log every few feet so the post would nestle in against the log, then we drilled matching holes in the log.

I could go into detail about the jig we used to drill the posts, or the pattern we used to align the posts properly, and a thousand other interesting details, but I need to wrap this up before you fall completely asleep! Suffice it to say the project was great fun and a terrific learning experience, and one I’ll never forget.

So again, if you’re looking for a great way to give back, get some terrific exercise, meet good people, and just plain have a good time out in the woods, look into Washington Trails or your local trail maintenance organization. You’ll be glad you did!

Dianne and Joe, Ed and JB, Bud and Marcella, and Dan pose on the mostly finished bridge – only the railings between the posts were missing – in the Okanogan National Forest, Washington.

All photographs courtesy of Joe and Dianne Hofbeck.

Thanks Ed and friends for making this bridge repair. It looks like a worthy project with a big impact for all.

You’re quite welcome, Myra!

Very nice piece Ed. Your blog is certainly a labor of love.

Keep in touch.